The difference between requesting samples from suppliers and skipping this step can likely determine the success or failure of a commercial operation in which a lot of time and money has been invested. Trusting that a supplier thousands of kilometers away, who speaks a different language and has a different way of understanding business, will accurately understand what product we want is still a beginner’s mistake that is best avoided.The need to request samples from suppliers lies in the fact that this is the only real reference for the merchandise that is desired to be imported. Sometimes, a mere description of materials, finishes, and qualities is not enough for the supplier to get it right the first time. A sample usually has a very low cost, it can even be free, paying only for transportation. It is a simple but crucial step that will prevent later disappointments.Requesting samples from suppliers is a necessary step in the import process to compare qualities, minimum order quantities, prices, and delivery times. Delegating to a comprehensive management company like Bull Importer simplifies this procedure and ensures better negotiation of conditions.

How to request samples from suppliers

The search for suppliers in Asia is a laborious process that requires a previous selection of candidates, evaluating their solvency, production capacity, commitment to delivery times, and compliance with standards and certifications. Likewise, prices and conditions must be compared.After discarding unqualified manufacturers, it is advisable to request samples from suppliers to compare qualities, finishes, and other requirements. Probably, manufacturers have samples from orders of other customers that may not match our specifications. It is essential to accurately specify the requirements regarding materials, components, and standards. In certain cases, it may be advisable to send a physical sample along with the specifications.Once the sample is received, its quality can be evaluated and modifications requested if necessary. These checks are of great importance, as the risk of ordering production without prior verification is very high.At Bull Importer, we advise our clients to perform this verification to save time, money, and disappointments upon receiving the merchandise. Furthermore, requesting samples from suppliers serves to discard unreliable manufacturers. When the manufacturer refuses to send a sample, we can strike it off our list of potential suppliers.The process is usually quick if a courier service is used, so in a few days, we will receive the samples. After comparing qualities and prices, we can choose the supplier that best fits our needs.To make the right decision, it is advisable to have sheets containing information about the product and the supplier:

- Company name

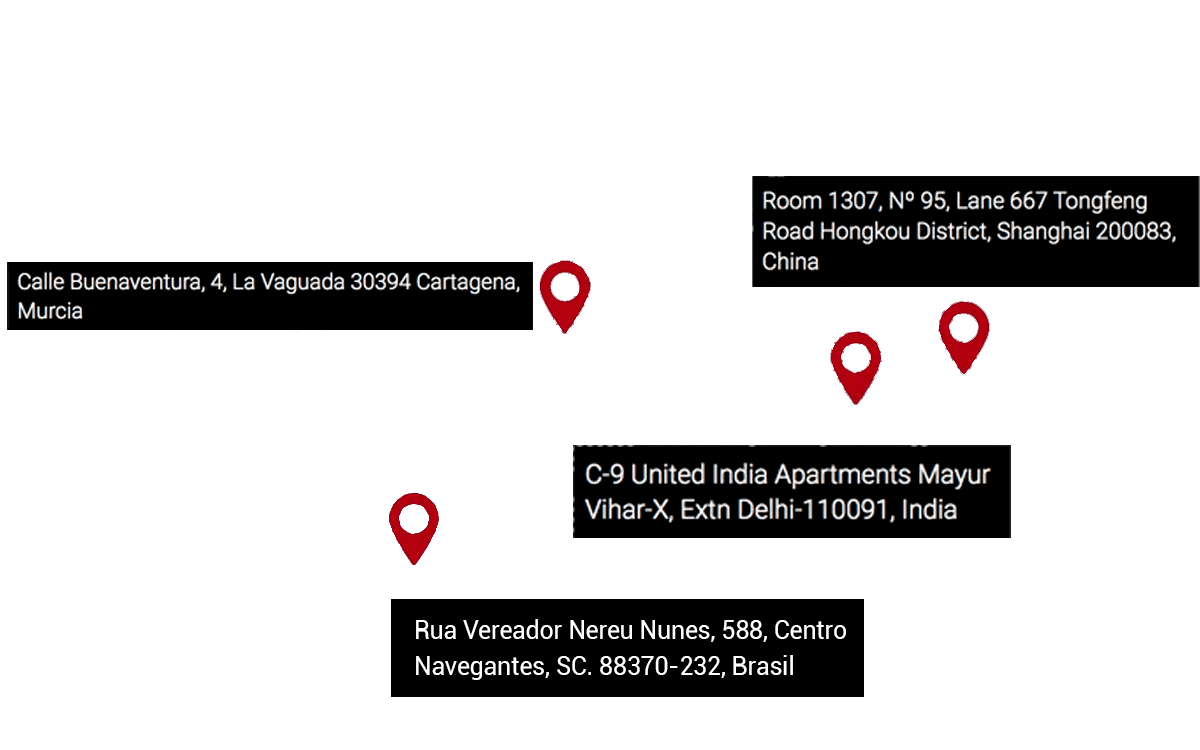

- Company details (name, address, phone, email, and contact person)

- Product description

- Price (always under the same conditions, for example FOB)

- Validity period of the quotation

- Quality certificates

- Type of packaging

- Minimum order quantity (MOQ)

- Delivery time

- Payment method

- Warranty

A space should be reserved for noting whether the samples meet expectations and if they have defects.With this comparison, we will be in a better position to choose successfully than if we skip requesting samples from suppliers before importing all the merchandise. In any case, remember that you can trust the outsourcing of your imports to Bull Importer.