- Raw materials that will be part of the manufactured products.

- Semi-finished products by the company that require further processing for sale.

- Finished products, which are manufactured by the company itself and intended for final consumption.

- Inventory of materials purchased by the company and intended for sale without transformation.

- Other supplies, such as replacements, packaging, or containers.

- By-products, such as waste that can be used or recoverable materials.

Importing companies must plan their supply well in advance to avoid economic losses, production stoppages, and brand image damage. Calculating the necessary stock and knowing when to place an order is easy using the Wilson model.

Proper inventory management involves having stored resources to prevent production stoppages, meet customer orders, obtain bulk purchase discounts, avoid unforeseen events such as delivery deadline non-compliance or unexpected demand increase, and cover seasonal sales peaks. Certain sectors, such as textiles, are more exposed to peaks in demand for certain products, such as warm clothing, swimsuits, school uniforms, sunglasses, and other goods that sell only at certain times of the year.

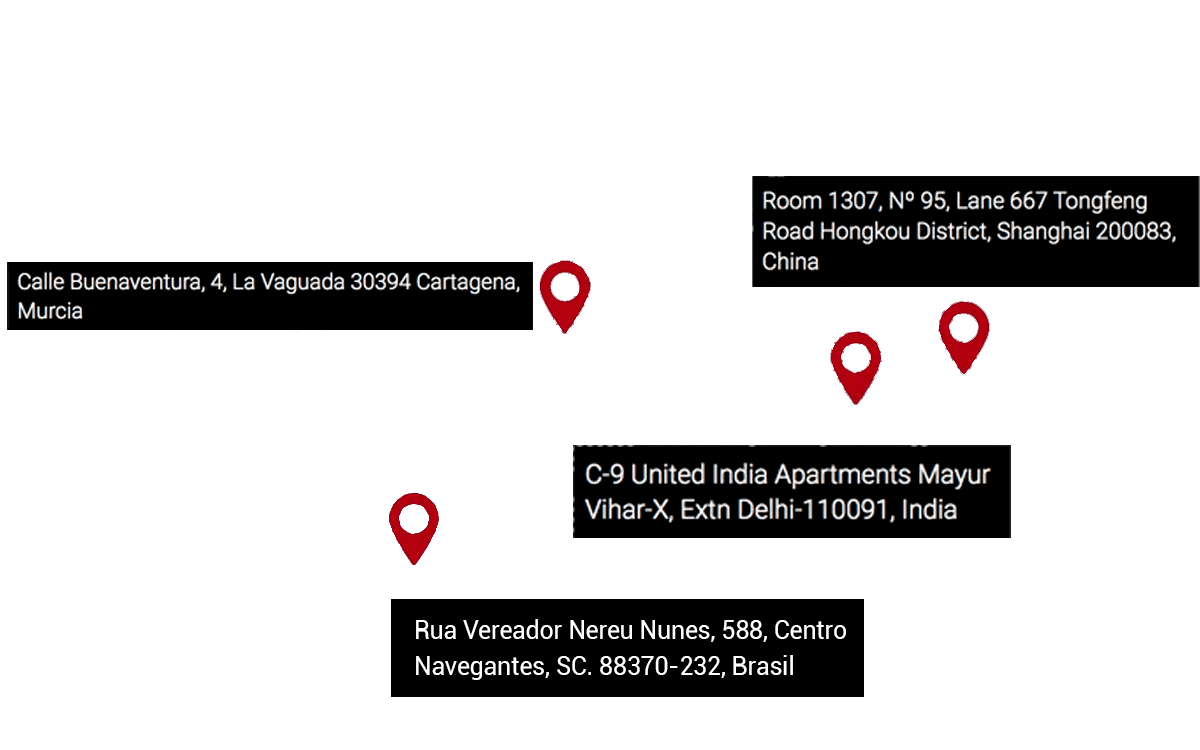

When merchandise is imported from Asia, meticulous stock management is essential, especially considering the time required for manufacturing and the long distances the order must travel from the departure port to the importer’s warehouses. Poor calculations can incur significant costs for the company economically and in terms of reputation.

Ultimately, it all comes down to a cost calculation that must coincide with the optimal import conditions—the minimum quantity of products for the operation and service times—with the seasonality of the supply and the physical storage capacity of the stock. To calculate the inventory management cost, three aspects must be considered:

- The administrative cost of managing and placing orders to suppliers.

- The acquisition cost or price of the product.

- The inventory maintenance cost, which includes management systems, handling equipment, insurance, logistics personnel, physical space, obsolescence, interest for financing to maintain stocks, and stock-out costs if the company runs out of stock to meet orders or production.

To reach the optimal supply point with minimal cost, one must precisely know which orders to place to maintain adequate stock and when. Proper planning must consider three indicators:

- Maximum stock, which is the maximum quantity of stock that can be stored.

- Minimum or safety stock, which is the minimum quantity of stock that must be maintained to prevent stock-outs.

- Order point, which is when the stock level requires placing an order to replenish in time. It is necessary to consider the time it takes for the supplier to deliver.