Less Than Container Load), meaning the goods will share the container with products from other suppliers. It is the preferred system for importers of small volumes who opt for group purchases.

Group purchasing or consolidation has many advantages, especially for SMEs, compared to FCL (full container load) shipping. However, LCL shipping for imports requires precise logistics coordination. Since the goods travel in a shared container, it is advisable to leave its management in expert hands to avoid delays or losses.

The LCL shipping modality is used when the imported goods do not fill a full container. It is a practical system for cost-saving as long as the logistics are handled by an experienced management company

How LCL Shipping is Done

Those wishing to operate this way must book the LCL shipping for imports with the freight forwarder, indicating the exact dimensions and weight of the cargo. Additionally, it is necessary to provide the relevant documentation, such as the Bill of Lading (BL), which signifies that the maritime carrier has taken charge of the goods, the commercial invoice, or the Packing List, a document listing the order’s contents, seller and buyer identification details, and the value of the cargo.

Generally, it is the freight forwarder who manages the cargo pickup and its transport to a consolidation warehouse where it is grouped. If the importer handles the operation themselves, they must ensure that the goods are well-prepared, packaged, and ready to be loaded.

Time Management in LCL Shipping for Imports

Groupage or LCL shipping for imports usually has a regular frequency, typically weekly or biweekly depending on the destination port. This makes correct time calculation crucial. Poor coordination can lead to significant delays in receiving the goods.

The goods must arrive at the consolidation warehouse well in advance. In this regard, it should be noted that the cargo must be at the warehouse at least 7 days before shipment. The farther the warehouse is from the port, the more time must be calculated for the delivery and consolidation of the cargo in the container.

Tips to Avoid Delays in Shipping

LCL shipments can be as fast as FCL shipments as long as everything is well-coordinated. The main risk of delays is the lack of control over the management of goods by other importers loading in the same container.

Some of the most common incidents include shipment delays because other importers do not meet deadlines, errors in the documentation of a shipment, or customs needing to conduct an inspection. Another common cause of delays is if the shipment’s destination is a secondary port, which would require a transfer and waiting for a ship to transport it to the final destination.

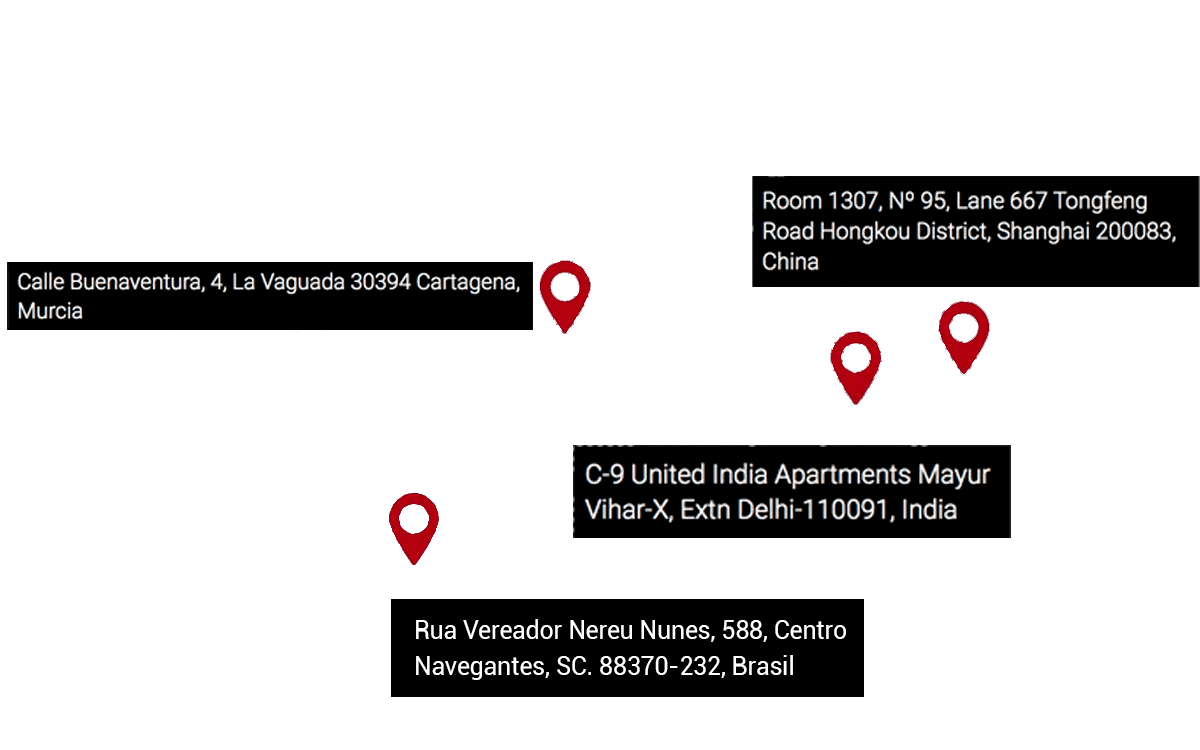

To avoid this problem, at Bull Importer we have a sophisticated group import service. We design a common strategy for all importers, efficiently coordinate the parties, and negotiate customization options for each group member.

Our LCL group import shipping management protocol includes specific software that controls the entire process, personalized order delivery picking for each member, joint or individual billing, and absolute confidentiality about each importer’s goods. This way, your goods will arrive on time and without incidents.

In the second part of this article,