Manufacturing in China is not complicated, but it requires knowing some basic aspects to control the production processes effectively and minimize risks. It is not so much about knowing the culture or business protocol rules but about monitoring the manufacturing process.

In the Asian country, you can manufacture with quality or without it. It all depends on the control when acquiring raw materials and the care in choosing a reliable supplier.

Manufacturing in China Without Sacrificing Quality

China has been immersed in a development plan called Made in China 2025 for years, aiming to consolidate its existing industries and promote innovation in production and quality improvement. This strategy seeks to forever eliminate the concept of manufacturing in China as synonymous with low quality.

Therefore, it is up to the importer to manage their production in China with minimal risks, either directly in that country or with the help of a company that offers advice for manufacturing or importing.

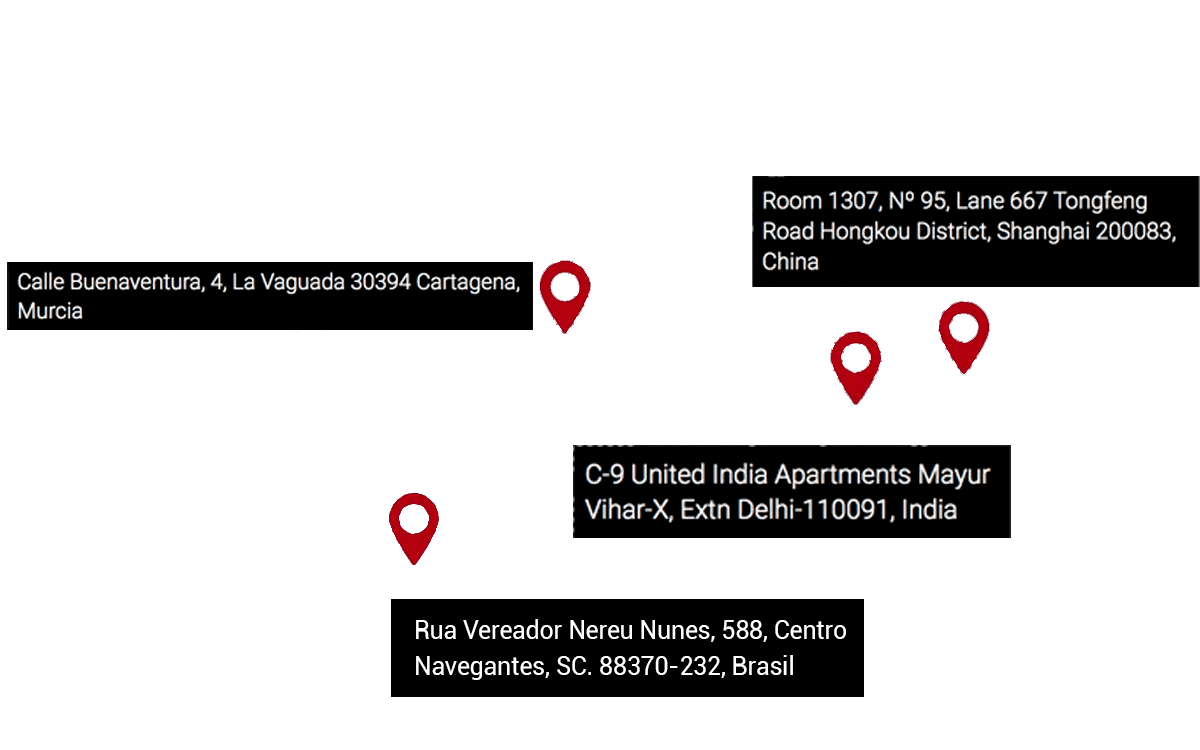

There are, of course, other options for manufacturing in Asia. The choice of one country or another largely depends on the type of goods. Even so, China remains one of the main exporting countries in the Far East and one of Spain’s largest trading partners.

Keys to Success in Manufacturing in China

If you are thinking of placing an order with a supplier in China, it is advisable to follow a scheme with all the essential points that require your attention. This will help you stay focused on your goal and maintain control throughout the process. This is the best way to minimize risks.

Define All Product Specifications

This first point is of vital importance. Note all the characteristics the product must meet, down to the most obvious details.

- Design

- Raw materials

- Accessories

- Colors

- Finishes

- Packaging

- Necessary certifications

The more detailed this list is, the better. Never leave anything to the supplier’s interpretation, as this can be the starting point for a chain of errors.

Select the Right Supplier

The right supplier is one who can prove they are capable of meeting all production requirements. Remember that it is your supplier who must adapt to the specifications, not the other way around.

Make an initial selection with suppliers who can guarantee the requirements. Then, begin negotiations to establish the contract terms.

Control the Production

Production supervision is essential, whether you do it in person or hire a management company. You should test the goods and, if possible, visit the factory personally. Besides the production chain, consider the shipping process. Poorly packaged goods may arrive in poor condition.

Follow Up

Following up on production allows you to get first-hand information to correct design or finishing problems. This way, you can fix mistakes in the future. Most importantly, you can let the supplier know about the issues so they can correct them if they want to continue working with you.

Product issues rarely reach the supplier because the information is not transmitted along the supply chain.

In summary, these four points are essential for manufacturing in China while minimizing risks. Although they are not the only ones, they are a significant part of your work as an importer.

Remember that at Bull Importer, we work to free our clients from all these cumbersome processes. With our services, you can manufacture in China comfortably, efficiently, and safely.