Traceability in importation is a fundamental process within product quality control that is often not given the importance it deserves. We can define this process as the scheme that allows us to follow the phases of a product from its origin until it reaches the consumer. Traceability in importation is key to detecting where a failure has occurred.

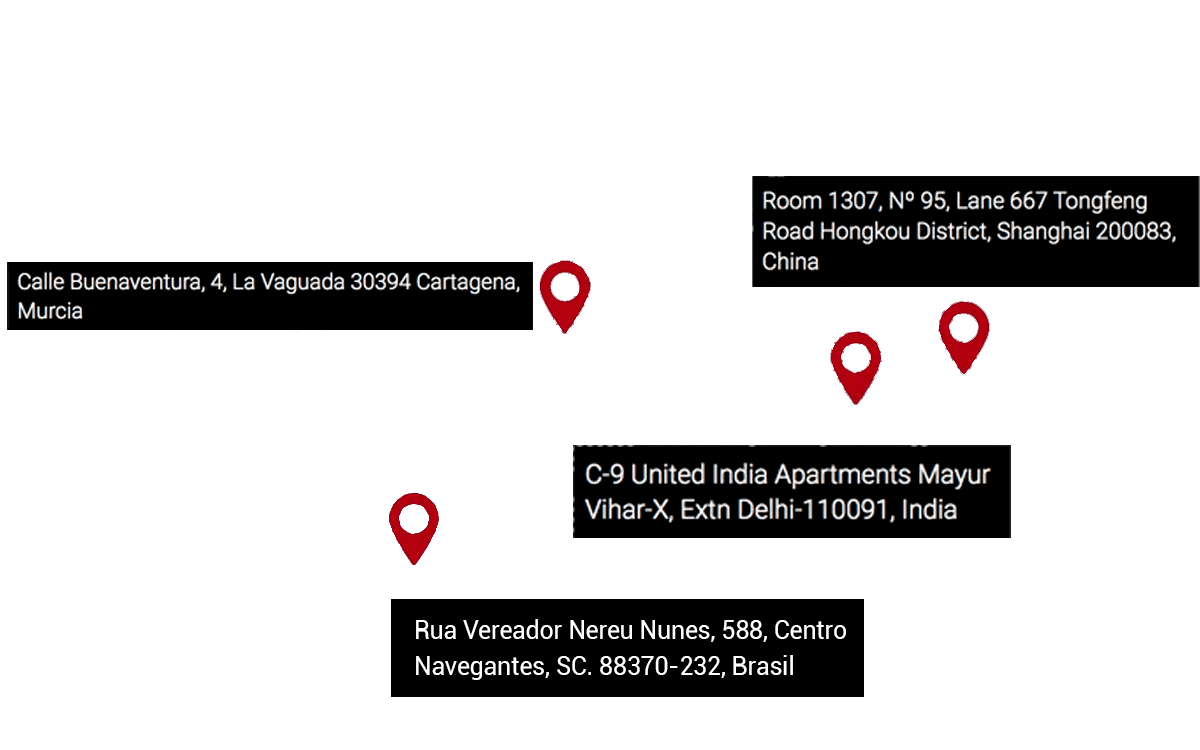

Imports from China or any other Asian country are complex commercial operations in which a lot of time and money are invested, so it is not advisable to leave the supply chain to chance. Thanks to traceability, we can reconstruct the history of a product stage by stage:

- Origin of raw materials

- Manufacturing phases

- Product location during transport

- Distribution tracking

Traceability is only mandatory for certain products, such as organic food, cosmetics, and furniture, but investing in this control system avoids major losses by being able to locate the exact point where a failure occurred

This process, fundamental in all types of importation, becomes especially relevant in certain areas, such as in the import of organic products, where the EU certification labeling is very stringent.

Another sector where traceability must be carefully maintained is in the import of organic extracts for food and cosmetics. Certification companies like Ecocert verify that the raw material comes from organic farming, which is essential to label the final product as organic.

A third example of the need for traceability in importation is furniture. The import of furniture is subject to controls by the Official Service of Inspection, Surveillance, and Regulation of Foreign Trade (SOIVRE) to protect consumers and ensure that furniture from third countries meets minimum quality, ergonomics, and safety standards. Importers are required to guarantee the traceability of references in their invoices.

What is traceability in importation for?

With a simple barcode, we can know step by step the history of a product from the time the raw material is obtained until it reaches the consumer. This allows us to reduce the probability of making mistakes and, more importantly, to know where and why they occurred.

At this point, traceability in importation is key, as it helps us in numerous situations:

- Failure in raw material

- Operator error

- Failures in the manufacturing process

- Problems with machinery

- Problems in transportation

Traceability is not mandatory for all products but it is highly recommended to ensure the quality of products imported from China. In some cases, control is carried out product by product, but in others, batch control is sufficient.

The involvement of China in traceability is increasing. The goal of the Chinese government is to increase confidence in their products, so they are in the process of implementing a traceability system, which is expected to be completed by 2020. The monitoring will apply to the main products exported by the country, especially in sectors such as agriculture, food, medicine, and dangerous goods.

With these measures, products imported from China will be able to shed the label of low quality that often accompanies them.

Traceability in importation is a complex process, so it is advisable to delegate its control to a specialized company like Bull Importer. The cost of implementing traceability will always be lower than the cost derived from a quality problem in a product without traceability.