PVC or Polyvinyl Chloride

PVC or polyvinyl chloride is the base material for manufacturing a multitude of products imported from Asia. From construction to toys, clothing, or footwear, importing PVC from Asia requires meeting certain requirements. Non-compliance with regulations can lead to severe penalties and ruin a business. The best way to import with guarantees is to know the requirements and specifications of PVC products.

PVC used in the industry can be rigid or flexible. Rigid PVC is mainly used in packaging, window profiles, doors, and drainage pipes. Flexible PVC has a wide range of uses: cable coverings, toys, footwear, fabrics, hoses, or bottles are just a few examples.

PVC is one of the common materials in products across all industries. Knowing the regulations and meeting the requirements for importing PVC from Asia is essential to avoid penalties, errors, and production delays.

Various techniques are used to mold PVC, such as calendaring, extrusion, injection, blow molding, coating, casting, or rotational molding, among others. Depending on each process, certain types of PVC may contain substances restricted in the European Union, such as phthalates. Not all Asian manufacturers consider the necessary certifications to import PVC into Europe, so it is necessary to indicate these restrictions in the product specifications list.

Requirements for Importing PVC from Asia

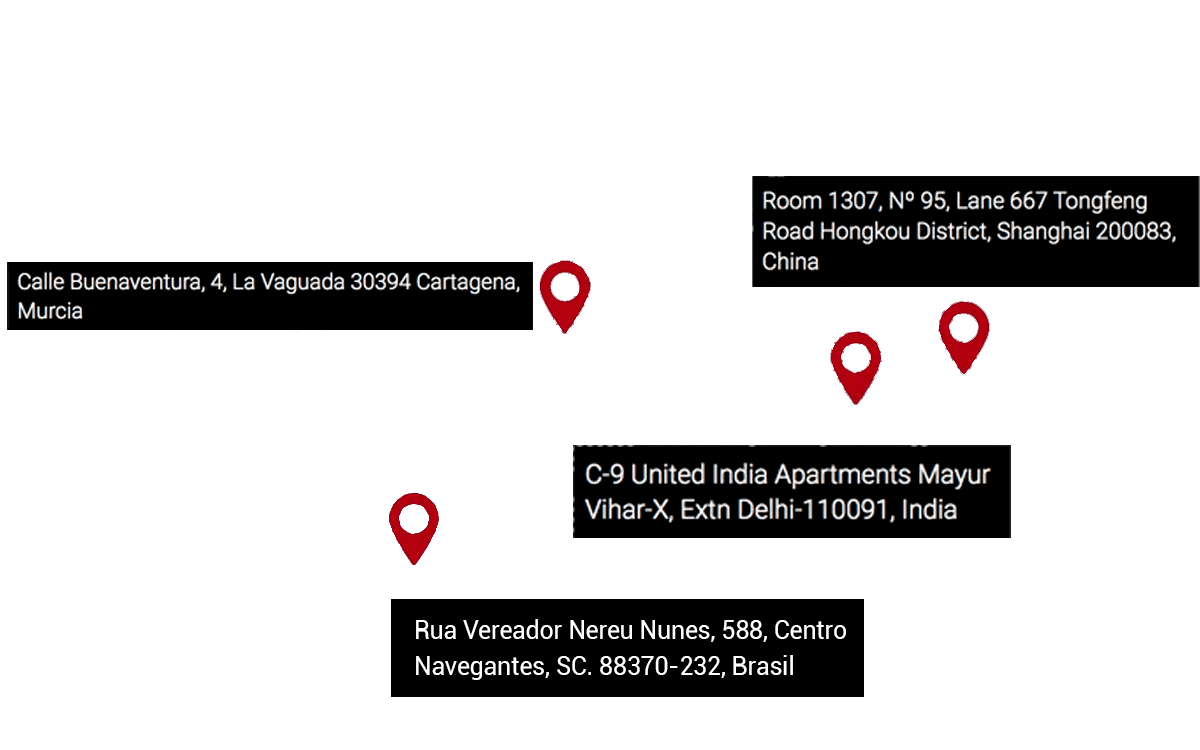

Importing PVC products through uncertified intermediaries is a risk not worth taking. The most reliable way is to handle the transactions directly with the manufacturer or a supplier that guarantees compliance with the relevant certifications and approvals.

It is a common mistake to trust that Asian suppliers know the certification standards and restricted substances. For example, only about 10% of Chinese manufacturers produce phthalate-free PVC, a crucial requirement for importing into Europe. Bull Importer works with PVC manufacturers capable of meeting current regulations.

Certification requirements vary depending on the final use of the PVC. The main standards refer to phthalates and flame retardants:

- Phthalates. These substances are used to increase the flexibility of PVC. However, phthalates are considered harmful to health and are prohibited in toys, for example. The phthalates that cannot be present are recognized by their acronyms: DEHP, DBP, DIBP, BBP, DINP, DIDP, DPHP, DIUP, and DTDP. A laboratory test is the only way to guarantee the absence of these substances regulated by the REACH regulation in Europe.

- Flame Retardants. Flame retardants are necessary in PVC used in construction and furniture. Depending on the product and its use, each country applies its own regulations on retardants.

Additionally, many PVC products must obtain certificates to meet specific requirements set by regulatory authorities in each country. Among them, PVC pipes for potable water supply must be certified by the National Sanitation Foundation (NSF International). This certification assures suppliers and consumers that the manufacturing process of a product has been independently reviewed to verify compliance with safety, quality, sustainability, and performance standards.

Specifications for Importing PVC Fabrics

Product specifications for importing fabrics containing PVC affect quality and durability. The supplier must know in detail the characteristics of the PVC fabric to meet quality standards and regulations.

- Coated or Laminated Fabric. PVC coated fabric is the most used for industry and construction. PVC laminated fabric is commonly used in toys, furniture, advertising tarpaulins, stain-resistant tablecloths, and clothing.

- Fabric Weight. The weight of PVC fabrics is indicated in grams per square meter. The weight of PVC fabrics largely depends on their final use. For example, for construction tarpaulins, the weight ranges from 550 to 700 grams per square meter (gsm), compared to furniture, which is around 300 to 400 grams per square meter.

- Width. Generally, PVC fabrics are manufactured in rolls. The standard maximum width is 3.2 meters, although some manufacturers can reach widths of 5 meters.

- Colors. To achieve the exact color, it is best to provide the Pantone® or RAL color code, chromatic guides that allow colors to be reproduced with complete reliability. If it is not possible to indicate the color code, the best alternative is to provide physical color samples.