OEM (Original Equipment Manufacturer) is used to identify manufacturers that offer the possibility of producing designs as white-label products for the buyer to customize with their own brand. Any company can acquire quality OEM products in Asia, as this is the most common form of production on the continent for items across all sectors.

The process of manufacturing OEM products is straightforward when assisted by an expert like Bull Importer, who manages all stages from selecting the supplier to beginning production. Professional advice is the best way to avoid complications and headaches that may arise during the various phases:

When manufacturing OEM products, the buyer specifies the design, Pantone colors, labels, materials, and packaging, and the manufacturer prepares the product according to these guidelines.

Destination Country Regulations

Each country requires compliance with a series of directives for product imports. Some refer to prohibited substances, while others impose requirements related to safety (e.g., for toys).

Specifically, in the European Union, common regulations must be met for all member states, plus specific regulations for each country. It is crucial to know the applicable regulations for the OEM product you want to manufacture and ensure the supplier can comply with them.

Product Labeling Requirements

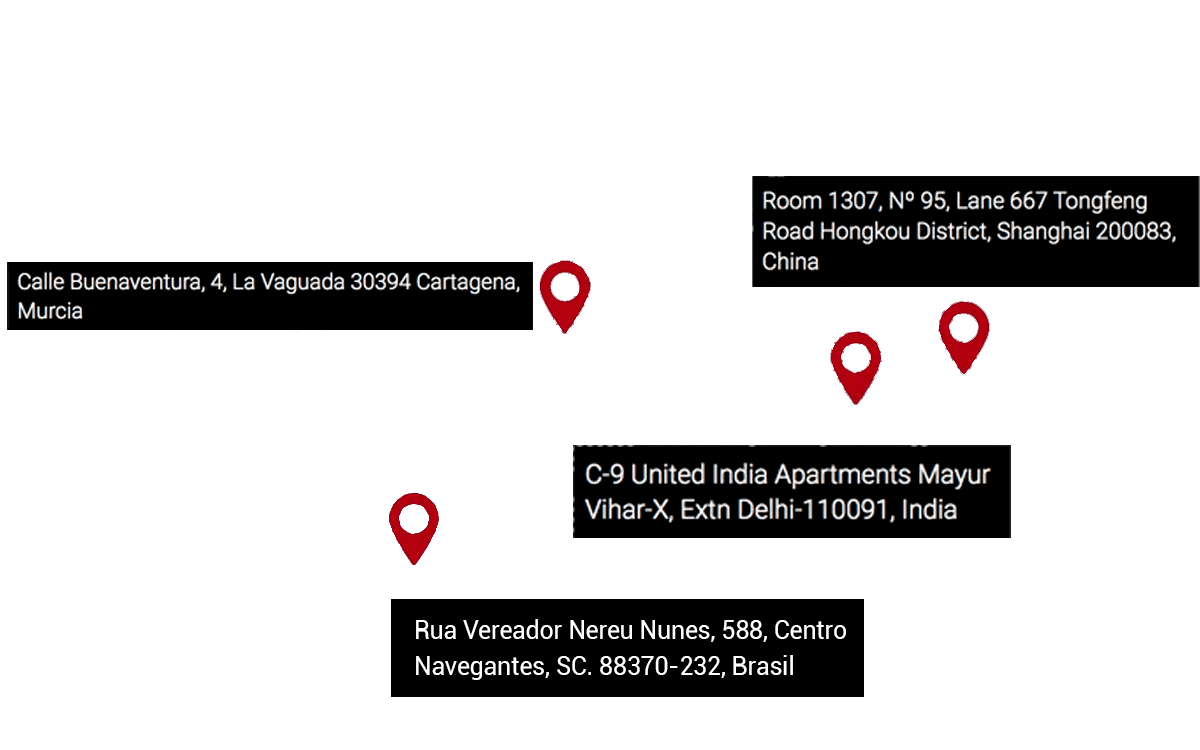

In addition to regulations related to substances and safety, import guidelines also mandate compliance with labeling standards. The most common labeling requirements include indicating the seller’s name, contact information, address, country of origin, and some usage warning symbols.

The European Union mandates the inclusion of the CE mark with a minimum diameter of 5 mm on the product unit, packaging, and user manual (if applicable).

Supplier Reliability

Before proceeding, it is essential to confirm whether the supplier can meet all the requirements for the OEM product you intend to manufacture. Not all suppliers have the means to produce according to European and Spanish regulations.

Product and Design Specifications

OEM manufacturers in Asia create products based on the buyer’s specifications. Therefore, the buyer must provide all details to the manufacturer, no matter how trivial they may seem, and leave nothing to the imagination. This is the only way to avoid misunderstandings due to cultural and language differences. Documenting the design and specifications helps prevent these issues.

The design should include a sketch with exact dimensions, the logo, label design, color samples, material examples, and compliance requirements. Being vague, using expressions like “good quality fabric” instead of specifying threads, weights, and Pantone colors can lead to multiple interpretations far from what you have in mind.

Sample Production

Before starting to manufacture the OEM product, it is necessary to verify if the supplier can produce the product with all the requirements. The only way to be 100% sure is to request a sample. This step allows for necessary checks and corrections before production. It is advisable to request samples from more than one supplier simultaneously. In case one needs to be discarded, you are not left without options.