Importing Serum and Oil Filling Machinery

These machines, sourced from the most advanced manufacturers globally, are designed to meet the specific needs of industries handling viscous liquids such as serums and essential oils. The technology of these machines ensures precise and efficient filling, resulting in a significant improvement in productivity and the quality of the final product.

Features of Serum and Oil Filling Machinery

These machines, designed for filling liquids with different levels of viscosity, are equipped with automated control systems that ensure precise dosing in each container. This is particularly important for products like serums, where accuracy is key to maintaining product consistency and effectiveness. Additionally, the machinery typically features flexible configurations that allow it to adapt to various container sizes and types, maximizing its utility across different production lines.

Importing Droppers Filling Machines

The droppers filling machines are essential for industries that require extreme precision in filling small volumes, such as the cosmetics and pharmaceutical sectors. These machines, imported from specialized manufacturers, are designed to handle operations where the margin for error must be minimal. Their ability to minimize waste and ensure exact dosing is crucial for high-value products.

Technologies Incorporated in Droppers Filling Machines

These machines are equipped with advanced control and automation systems that enable meticulous and consistent filling. Precision sensors and valves ensure that each drop of liquid is accurately measured and dispensed. Additionally, many of these machines feature automatic adjustment capabilities that allow for quick changes between different filling volumes, making them ideal for production lines handling multiple products.

Applications and Benefits of Filling Machinery

The filling machinery, imported from leading global manufacturers, is a strategic investment for any company looking to enhance its production capacity. These machines are versatile and can be used across a wide range of sectors, from food and beverages to chemicals and cosmetics. Their design allows for fast and precise filling, reducing material waste and ensuring uniformity in packaged products.

Adaptability and Flexibility

One of the greatest advantages of these machines is their ability to adapt to different types of products and containers. This means that a single machine can handle multiple production lines, leading to greater operational efficiency and a quicker return on investment. Additionally, their integration with existing automation systems makes it easier to expand and modernize production lines without requiring significant structural changes.

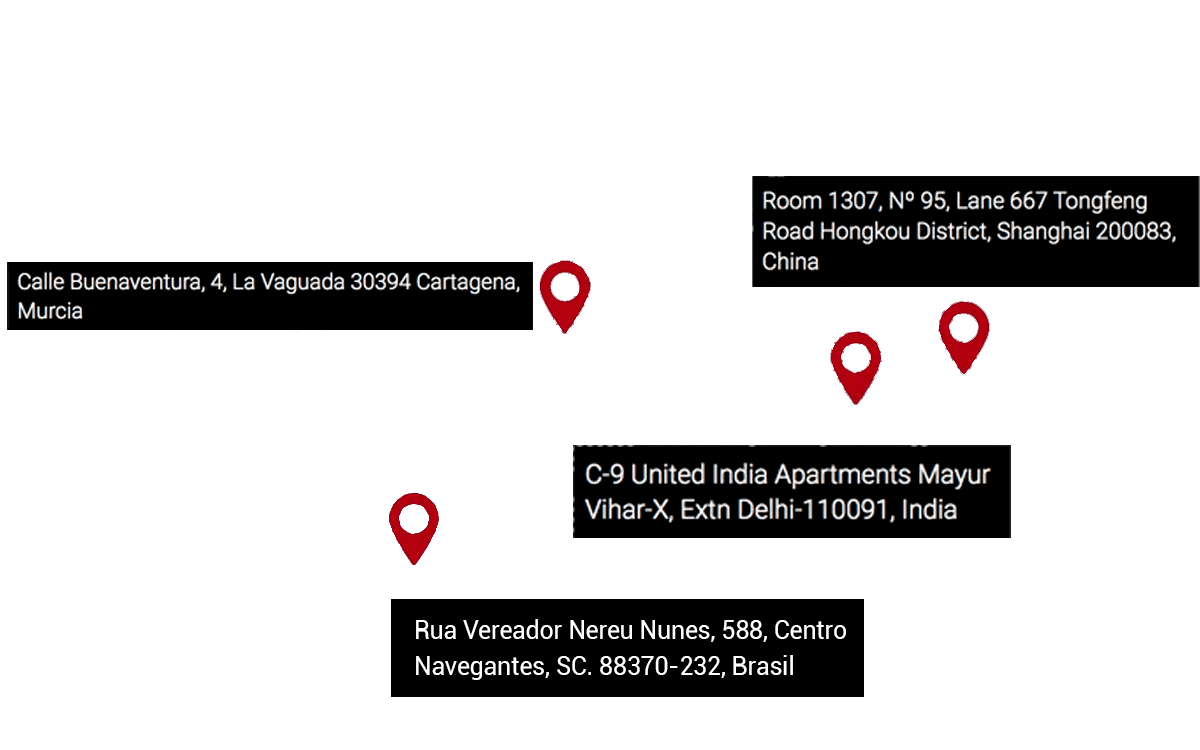

Why Import Machinery with BullImporter

Choosing BullImporter as your partner for importing filling machinery ensures an efficient and hassle-free process. With an extensive network of industry contacts and deep market knowledge, BullImporter selects the best manufacturers worldwide, guaranteeing that you receive only high-quality equipment.

Comprehensive Support Throughout the Import Process

BullImporter not only facilitates the acquisition of machinery but also provides comprehensive support throughout the entire process. This includes expert advice on selecting the right equipment, handling customs procedures, and coordinating logistics for timely delivery to your facilities. Additionally, we have a dedicated customer service team to address any inquiries or issues, ensuring a smooth and efficient import experience.

Advantages of Automatic Filling Machinery

Importing automatic filling machinery offers multiple benefits that can dramatically transform your operation. These machines are designed to optimize production, reduce waste, and ensure a high level of precision at every stage of the process.

Improved Efficiency

Automatic filling machines significantly increase production speed with less need for manual intervention. This not only speeds up the process but also reduces operational costs by minimizing the time and effort required to complete each production batch.

Precision in Filling

Thanks to the advanced technology they incorporate, these machines ensure exact dosing in every container. This is especially important in industries where product consistency is vital for customer satisfaction and compliance with regulations.

Versatility and Easy Integration

The versatility of these machines allows them to handle a wide range of viscosities and container types, making them ideal for companies that produce various types of products. Additionally, their modular design facilitates integration with other existing production and automation systems, allowing for quick and hassle-free expansion.

Do You Have Questions?

Contact Us