What sets us apart

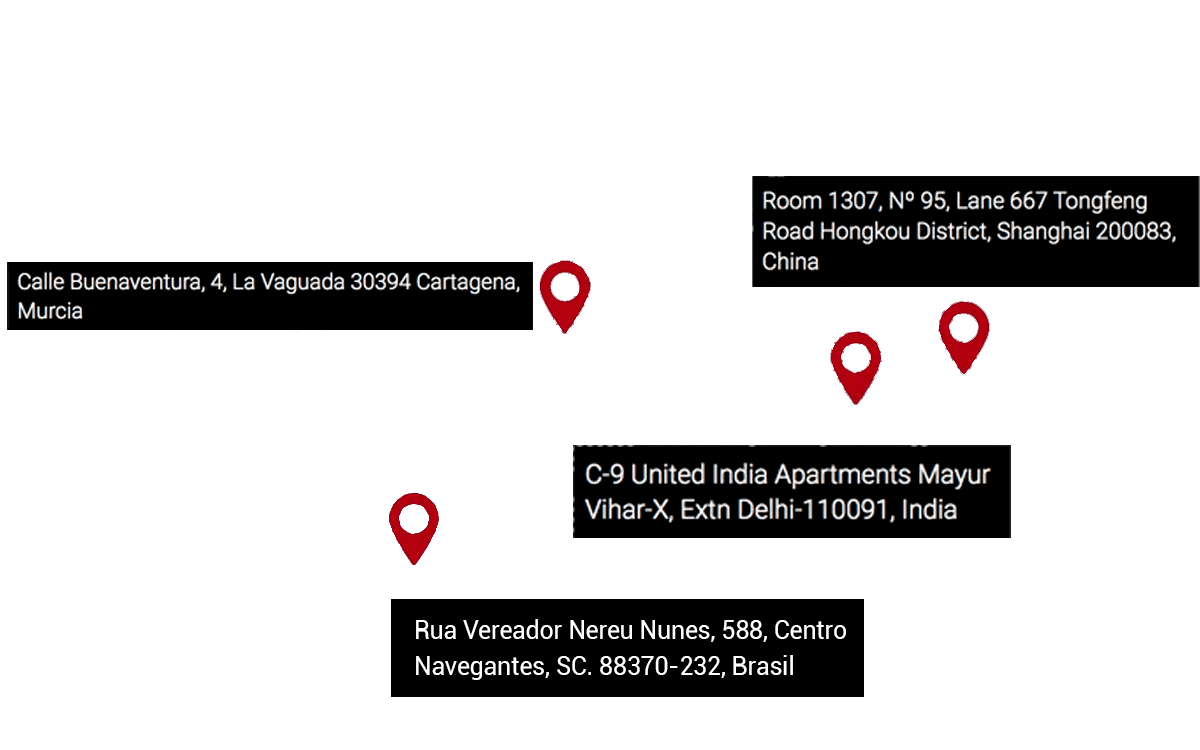

At Bull Importer, we have been helping companies buy from China, India, and other countries for over 25 years, customize manufacturing, and manage the import process comprehensively through a unique procedure in Europe that allows importing with a single company in a controlled and secure manner.

How do we manage product importation for companies?

Total Financing: Bull Importer, in collaboration with Spain’s largest bank, has developed the first economic model enabling SMEs to finance 100% of the importation cost.

Total Coverage Insurance: Bull Importer ensures full coverage of the operation with cargo insurance for 100% of the importation cost through a significant European insurance company.

All Operations on One Invoice: Conveniently pay for your importation with a single invoice in euros, financed according to the agreed-upon terms, without dual currencies.

Headache-Free Security: We oversee all phases of the process to ensure the safety of your importation and compliance with agreed-upon standards. We inspect merchandise at the source through our international offices.

Product Liability Insurance: The product’s liability insurance protects you from damages that may arise from the handling of the product to third parties initially, including end-users of the product and stakeholders in the value chain.

Efficient Strategies for Smooth Importing or Manufacturing Abroad

When it comes to manufacturing products or importing items from countries with lower costs, you can choose the long way or the short way. The long way is a true headache, even if you hire occasional support from other import agencies.

The short way, with Bull Importer by your side, is done without worries, with total security in all operations and maintaining absolute control over what you want to manufacture or import, under what conditions and deadlines, and with what quality. It’s a comprehensive, efficient, rigorous, and convenient service.

Those who decide to import on their own stumble, time and again, due to language barriers, cultural misunderstandings, seemingly endless international bureaucracy, unexpected intermediaries seeking payment, currency exchange messes, deadlines never met, and fear that the merchandise might get stuck in customs due to unsolvable problems.

Those who choose Bull Importer don’t face these issues. Once the specifications of the item they want to import (basic features, characteristics, quality, and quantities) or the products or components they want to manufacture (preparation and translation of blueprints and projects, management of designs or molds, selection of quality and quantity criteria) are defined, they are relieved of the most arduous work:

Supplier or Manufacturer Location: If you don’t have a list with indications of manufacturers capable of producing the item or component, or specialized suppliers for the product you want to import, a very long investigation of candidates begins in distant regions where it’s even difficult to communicate in English. It will be challenging to have a comprehensive view of the producers and suppliers of the interesting item, and there’s a risk of hiring one who isn’t the best in that field.

Verification of Business Solvency: Once the stage of locating the supplier or manufacturer is surpassed and with a reduced list of candidates in hand, they must be examined to see which one deserves our trust—and our money. Without being an expert or having our personnel in the country, it will be difficult to obtain verified financial reports of the manufacturer or reports on their commercial specialty, shareholder composition, the type of suppliers they have, and their reputation regarding contract fulfillment. And these are basic data for selection.

Inspection of Facilities and Processes: Even if preferences have been established, a choice cannot be made yet. It is mandatory to visit their facilities to see if they have the actual capacity to produce what is ordered in the agreed-upon quantities and within the appropriate timeframe. It will also be necessary to see what stock they keep in their warehouses to determine if they are reliable.

Supplier Quality Audit: At this stage, things are very clear. We know what we want. Quality is not just a matter of price; it’s a matter of industrial capacity and choosing the best processes. Before making a decision, it will be necessary to audit the candidate for manufacturing or supplying our items to understand their quality processes and the actual error tolerance margins they exhibit.

Comprehensive Solutions

Bull Importer’s clients have bypassed these four steps. They receive a comprehensive report with candidates offering the product that fits the specifications from anywhere in the world, not just in China or India. For each manufacturer or supplier, the report includes a summary of their business solvency, the result of personal inspection of facilities, and all data collected about their quality processes. Bull Importer’s clients only need to choose whom they want to work with from the list of the best presented in the report.

Those who have not yet opted for Bull Importer’s comprehensive solution continue with the process:

Negotiating the Price: All factors—unit price, quality, quantity, and delivery time—come into play in a negotiation where currencies and payment methods (letters of credit) play a fundamental role and contribute to confusion. It’s important to remember that the concept of time frame may differ from ours and that an excellent price for quantity may depend on the manufacturer appropriating less protected ideas.

Requesting Samples or Prototyping: Before signing the contract, it’s crucial to verify that the gathered reports reflect reality. Samples of the desired imported item matching the desired specifications should be requested to confirm the supplier’s capability to supply them. It’s also mandatory to request the manufacture and delivery of prototypes of the product or component desired for manufacturing. The process, in the case of manufacturing, is more complex because it requires handing over data and patents to a potential supplier, which must be legally protected.

Negotiation of Financing: The importer’s bank comes into play. Negotiations regarding the terms and the final amount of the operation must take place before signing the definitive contract with the supplier or manufacturer. At this stage, only the purchase or manufacturing price of the product is certain. The price of transportation, certifications and approvals, or tariffs still needs to be considered. Everything else is just estimates. Obtaining a good financial price won’t be easy.

Meanwhile, Bull Importer’s clients have a dossier on the table with the proposed contract from the chosen supplier and the most advantageous negotiated price. Along the way, they have been able to verify the quality of the samples or the efficiency of the manufacturing process in producing prototypes.

They don’t even have to negotiate partial financing for the importation because from the beginning, they have had financial management covering the entire value of the operation, including the costs of the management service. The decision to sign the contract is in their hands.

Once signed, those who import or manufacture without Bull Importer’s support continue to struggle with their outsourced suppliers or manufacturers:

Deadline Monitoring: It’s essential to establish control milestones throughout the process and ensure that the manufacturer or supplier is meeting them. The difficulty lies in the fact that the concept of time frame and production planning differs from ours due to cultural differences. A period of 30 days can turn into 120 days for us because the start of the deadline differs from our Western logic. The importer will succumb to despair more than once.

Quality Control: It’s necessary to visit the factory again to ensure that the result meets the quality parameters established in the contract. It’s important to review that the items to be imported meet all the same quality characteristics. If there is no personnel in the manufacturing country, managing the entire operation becomes complicated. If quality control is not met, it’s necessary to demand the correction of defects according to the contract or seek compensation.