The acquisition of large phenolic boards that then need to be processed to be useful in the production process is a thing of the past. For its main consumers, construction companies, furniture manufacturers, and outdoor equipment, they have ceased to be a raw material to become finished pieces that are integrated into the production process in a timely manner. Manipulation and adjustment costs disappear, and the delivery times of the finished product are accelerated with the importation of custom phenolic boards.The production of widely used furniture for outdoor use, children’s play equipment, technical floors, and many others that use phenolic materials have incorporated continuous improvement processes that bring these industries closer to just-in-time methodologies. The phases of producing pieces from large boards have disappeared.Importing custom phenolic boards reduces costs and delivery times, improving the productivity of construction companies.When the industry procures, it specifies in detail the characteristics of the pieces it will use in its production process. The manufacturer is tasked with specific cuts, die-cuts, drilling, polishing, and finishes. Absolute precision is demanded in measurements, colors, and finishing treatments.During production, the manufacturing costs for the manufacturer are very low, so their impact on the final price is minimal.In return, the importer obtains fully finished pieces, properly certified, and ready to be integrated into the production process. Timelines are shortened, and products can be delivered to the end customer promptly and with all guarantees. And the importer gets rid of the management of waste resulting from the manipulation of phenolic boards, because it hasn’t occurred.

Tips for importing HPL phenolic boards

There are different types of phenolic boards depending on the material used in their manufacture. The three main types are:

- HPL phenolic boards made of kraft paper

- HPL phenolic compact boards made of wood fibers

- Phenolic or marine plywood, composed of several layers of wood superimposed perpendicularly. Ideal for outdoor use.

- Filmed phenolic plywood, used for stages, technical floors, and loading platforms.

The standard dimensions of the boards are 2440 mm x 1220 mm, with thicknesses ranging from 6 mm to 10 mm. The available color chart is extensive, suitable for any construction need.From these dimensions, it is possible to create any type of piece that may be needed.

Characteristics and applications of HPL phenolic boards

Gradually, phenolic boards are replacing other materials in production processes. The board is easily handled, can weigh less than ceramic, stone, or metal materials, yet maintains similar properties.HPL phenolic boards are made of cellulose or wood fibers impregnated with resins, subjected to high temperature and pressure. The outer faces can be decorated with colored sheets and resins. Among their main characteristics are the following:

- High hardness

- High mechanical resistance, impact resistance, wear resistance, and scratch resistance

- Hydrophobic properties

- Low porosity, making them antiseptic, antibacterial, and hygienic

- Resistance to heat, stains, and dirt

- Good fire behavior and non-conductive

- Easy installation

- Low maintenance and easy cleaning

Their versatility and enormous possibilities for customization in terms of dimensions, colors, and finishes make the demand for imported HPL phenolic boards from Asia clearly increasing. It is the ideal material for installations that require resistance and functionality. The most common uses are bathroom stalls, lockers, office partitions, pool and gym furniture, public bathrooms, and ventilated facades.

How to import phenolic boards from Asia

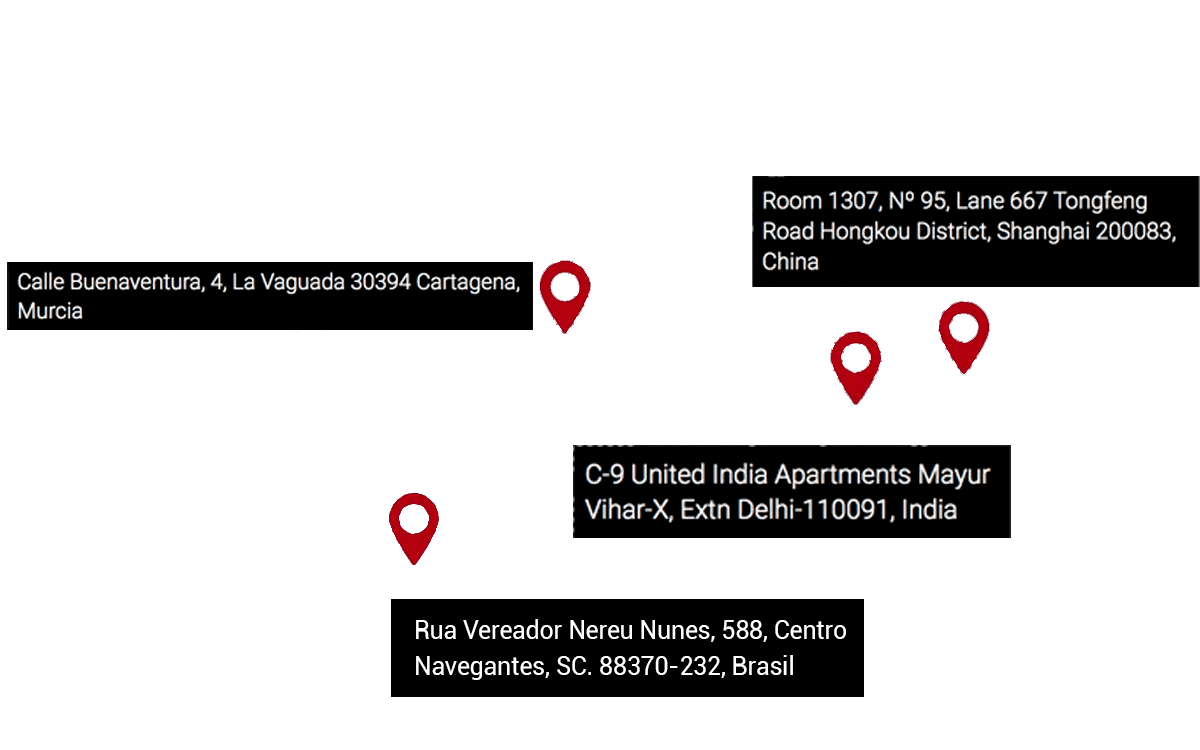

At Bull Importer, we manage the personalized import of HPL phenolic boards. They are always acquired from suppliers that comply with regulations regarding resistance, density, formaldehyde, and moisture absorption, and offer certified products.The request for pieces depends on the volume of the order to be placed. A detailed sketch of the cut and the position of dies and drills is required. A description of the final colors and textures, both single and combined, is also needed.It is also possible to import and manufacture in Asia other derivative products such as fiberboards (MDF) or melamine particle boards (MDP), veneered with wood or with resin film.